Redefining the standard of aluminium purification.

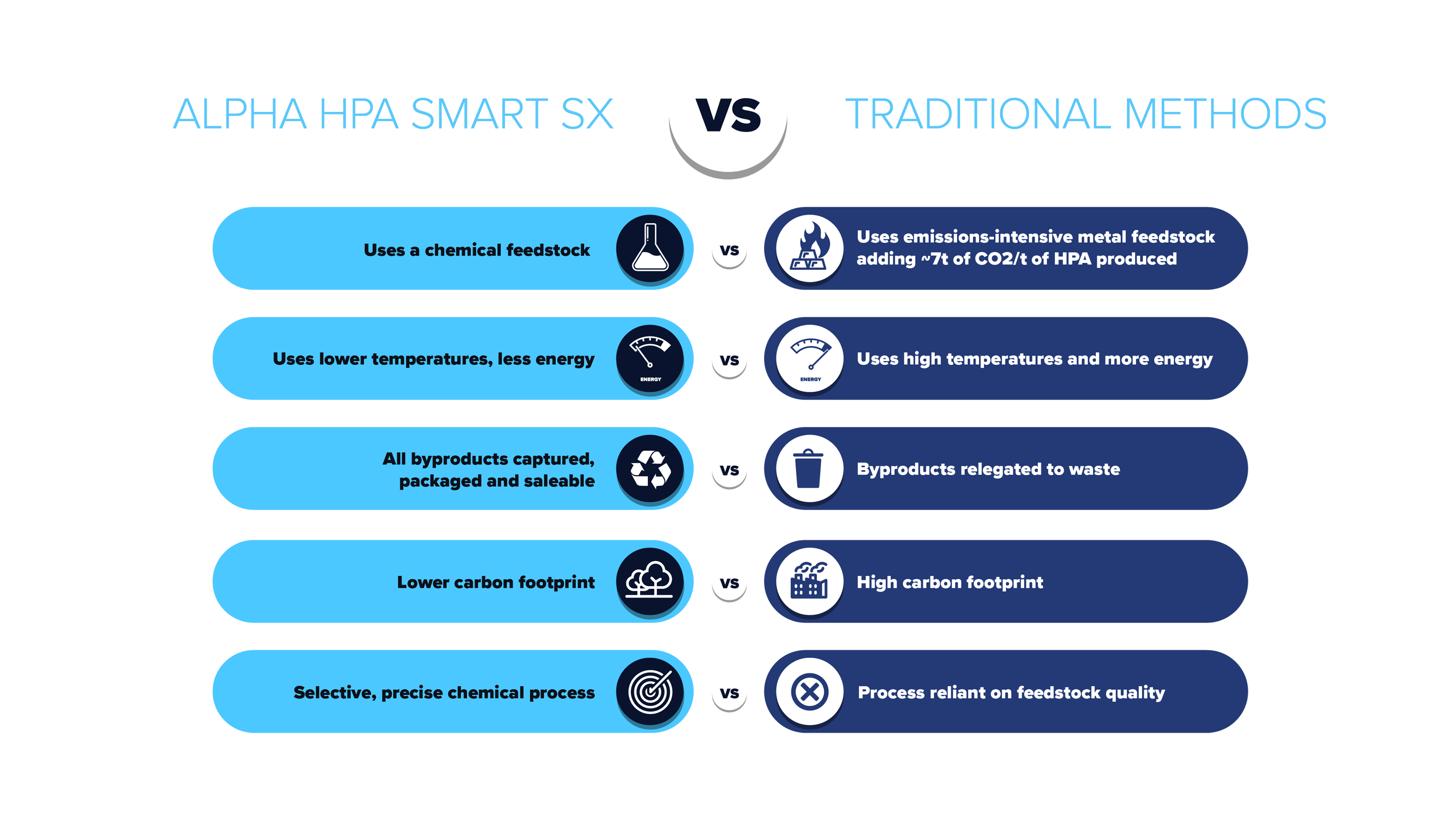

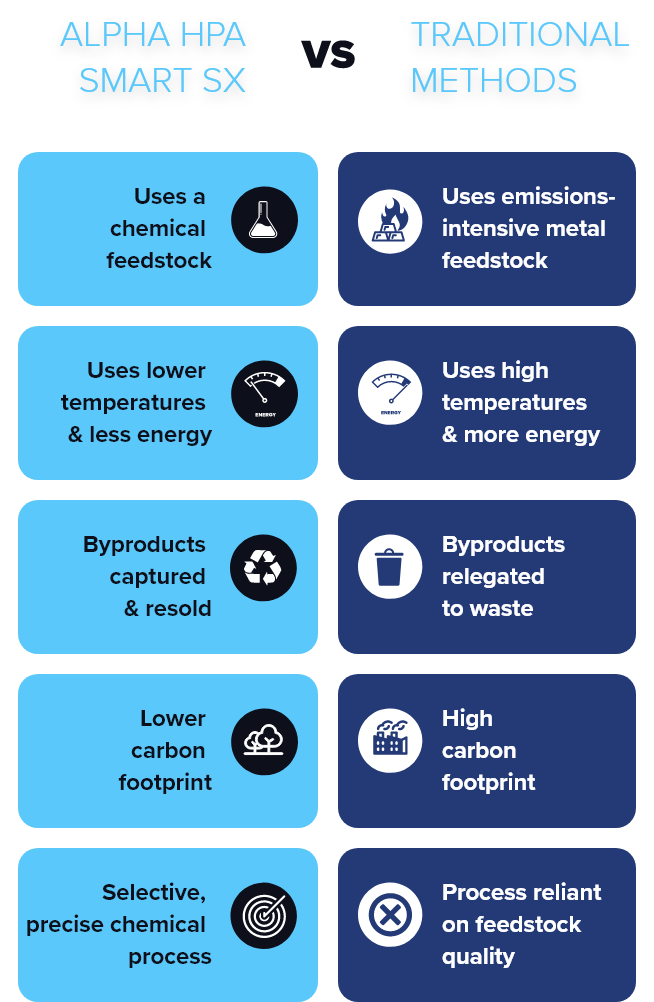

Our licenced Smart SX Technology is the world’s first, highly selective, scientific process, that extracts aluminium with pinpoint accuracy to create a wide range of ultra-high purity aluminium products, with dramatically less energy, emissions and waste.

Smart SX. A better, smarter way to purify aluminium

High purity aluminium products play an integral role in a number of technologies critical to the global energy transition, but aluminium is also one of the world’s most carbon-intensive industries, accounting for as much as 3% of global emissions.

Our applied Smart SX Technology sees up to 70 percent lower total carbon emissions in comparison to the incumbent high purity alumina process by:

- We do not use energy-intensive aluminium metal as our feedstock.

- We recycle our 100 percent of our key reagents as by-products.

- We use 100 percent renewable energy to power our plant.

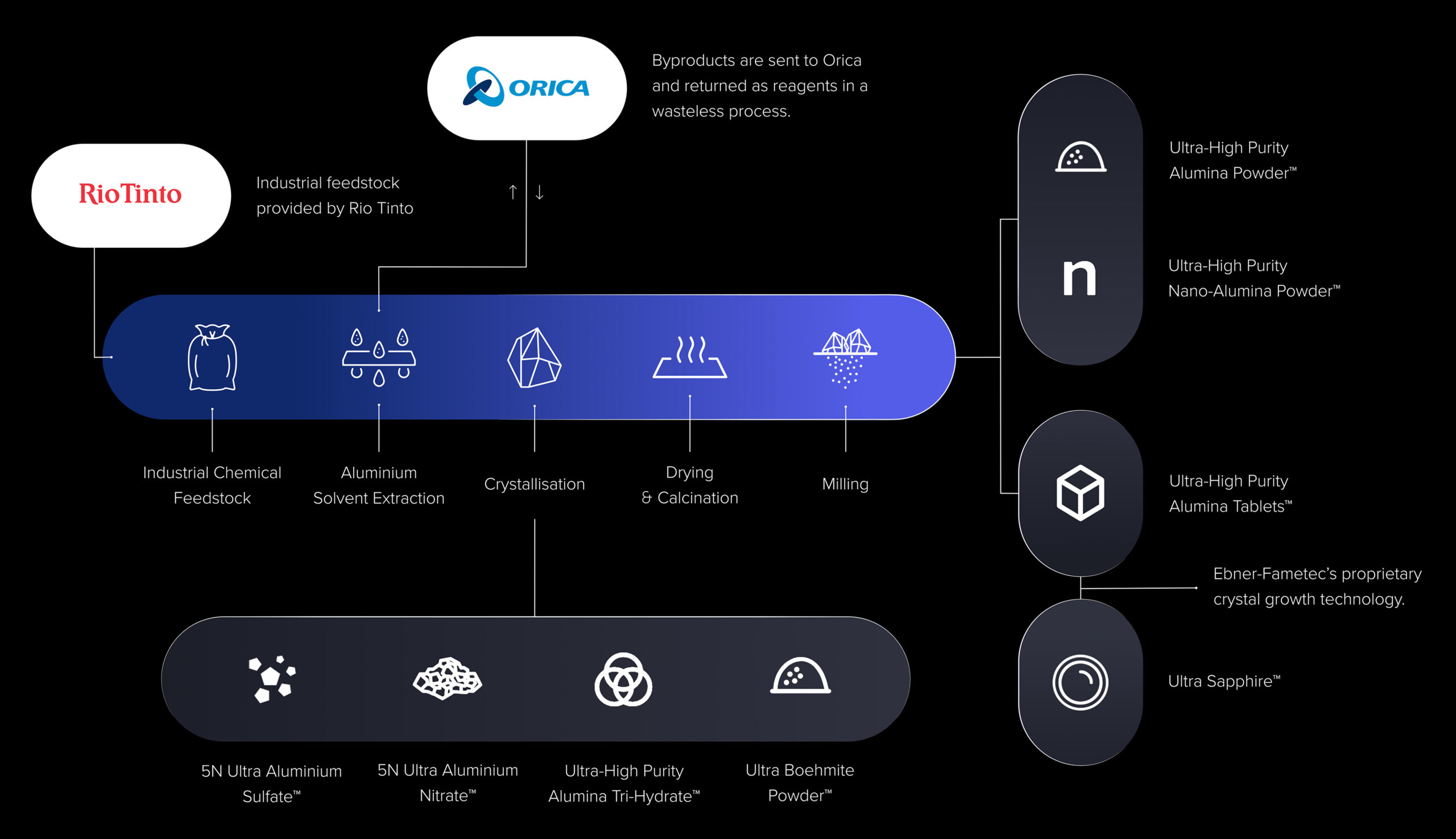

Science of Smart SX technology

Our Smart SX Technology process uses established solvent extraction, re-purposed to the highly selective extraction of Al3+ cations from an aluminium-loaded liquor. It transforms aluminium loaded organic (solvent) through two crystallisation steps into an intermediary product that can be calcined to high-purity alumina (HPA) with benign off-gases. The loaded organic stream can be directed to any acid stream to generate 5N+ purity aluminium precursors (salts), or 4N+ boehmite or alumina. The process recycles close to 100% of its process reagents and process streams.

The Smart SX process is simple, ingenious and flexible, purifying a common industrial feedstock into a range of ultra-pure aluminium products at high efficiency and low cost. Our technology uses no novel units of operation, but instead employs unique, proprietary process chemistry to deliver the first aluminium SX facility in the world.

The problem with traditional aluminium processing

The traditional methods for producing HPA lean on old, emissions-intensive technology. Under historical processes, HPA production is synthesised from aluminium metal feedstock, or produced from hydrochloric acid leach of kaolin clay. Both of these processes are extremely energy intensive, produce high carbon and chemical emissions, and create a significant amount of waste. Not only is this detrimental to the environment, it’s inefficient. Alpha HPA’s unique processes and products achieve industry-level purity with fewer emissions with near-zero waste.

We have redefined the standard of aluminium purification, to produce industry-shifting, sustainable, high-purity aluminium products – available in commercial quantities.

Our Products

ALSO EXPLORE