Alpha HPA has significantly expanded its global customer base, securing new sales orders from multinational companies including 3M, Merck, Entegris, Tokuyama and Saint Gobain.

This follows the company’s Final Investment Decision to progress to full scale production at Stage Two of its HPA First Project in Gladstone, Queensland.

The wave of new orders to the top-tier science, technology and construction conglomerates, highlights the critical role of Alpha’s advanced, low-carbon technology in the high-purity aluminium market.

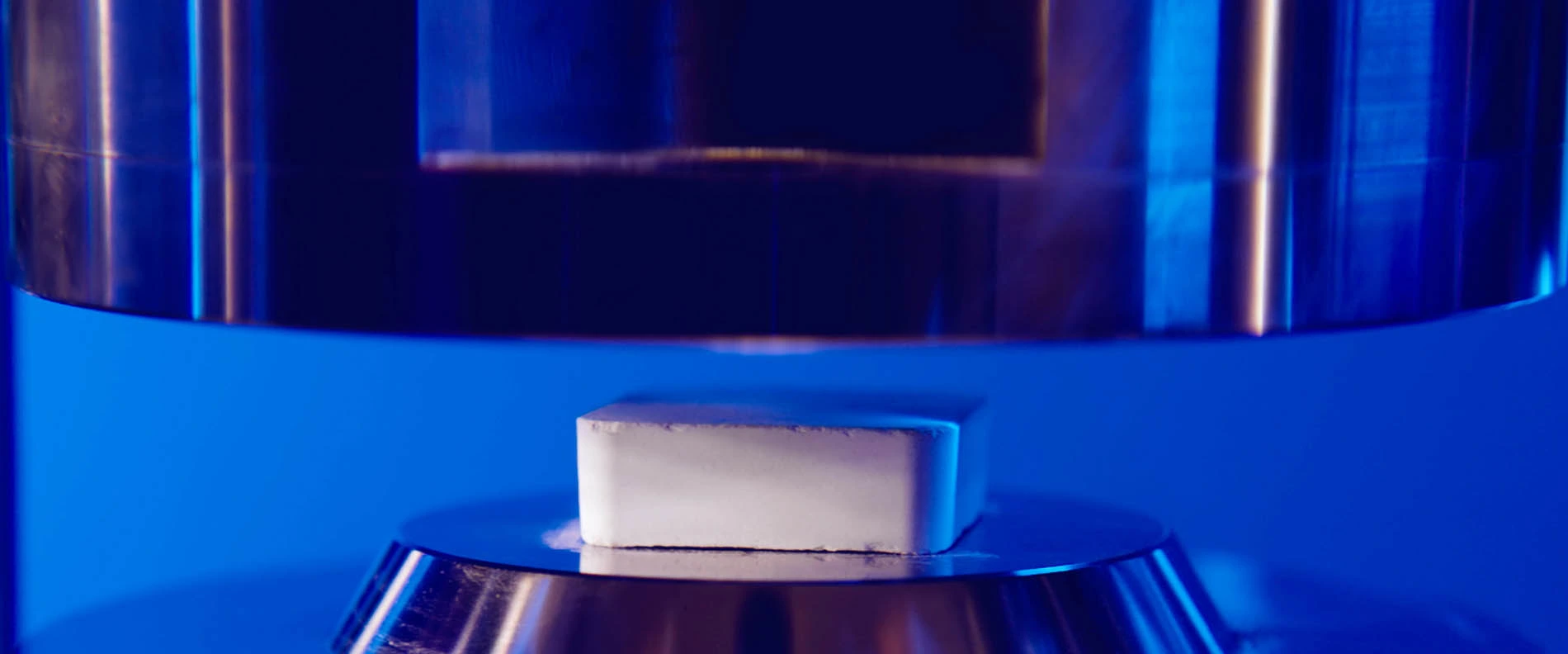

Alpha HPA’s proprietary process technology offers a unique opportunity to manufacture a wide range ultra-high purity aluminium material that are cost competitive, low-carbon and which leverages off established industrial infrastructure in Gladstone.

The innovative process allows for the extraction and purification of aluminium from industrial feedstock, producing materials of exceptional purity for high-technology applications, including the semiconductor, lithium-ion battery and LED lighting sectors.

“We are pleased to report that the company has recorded a material increase in product orders and increase in test order volumes and sales post FID of Stage Two,’’ said Alpha HPA’s Managing Director Rimas Kairaitis.

“In particular, multiple pre-commercial product sales have increased in line with the encouraging maturation of technical product qualification with multiple counterparties.

“In each case, pre-production sales are linked to material indicative sales volume to be serviced by the Stage Two facility.

“Alpha HPA is very pleased with the material acceleration in end-user engagement, qualification orders and product sales orders as we build momentum with our Stage Two Project execution,’’ he said.

In another significant milestone, Alpha has successfully filed a provisional patent for the UltraCoat process, which utilises Alpha’s proprietary ultra-high purity Al-Nitrate precursor to apply controlled thickness high-purity aluminium-oxide and hydroxide coatings to a range of surfaces within the Li-B cell environment.

The product is a fire-reduction technology to improve lithium-ion (Li-ion) battery safety.

The Company’s Stage One, Precursor Production Facility in Gladstone, QLD has established small scale commercial production for its full range of high purity aluminium products including 5N aluminium nitrate precursors and 4N5+ purity aluminas (HPA) and high purity alumina hydrates.

In May 2024 the Company took a Final Investment decision (FID) on Stage Two of the HPA First Project, representing the full commercial scale implementation of Alpha’s proprietary aluminium purification process technology.

Since the FID, Alpha HPA has progressed the project in significant areas such as completing a multi-week hazard and operability study, recruiting key staff, and advancing layout and civil design for the expected start of earthworks from September 2024.

In parallel, Alpha HPA continues to advance its complementary downstream Alpha Sapphire business, completing installation of the initial two sapphire growth units and successfully completing its second round of sapphire growth.

Ends.

Media contact: Ellie Blumel – +61 (0) 448 122 948 or eblumel@alphahpa.com.au