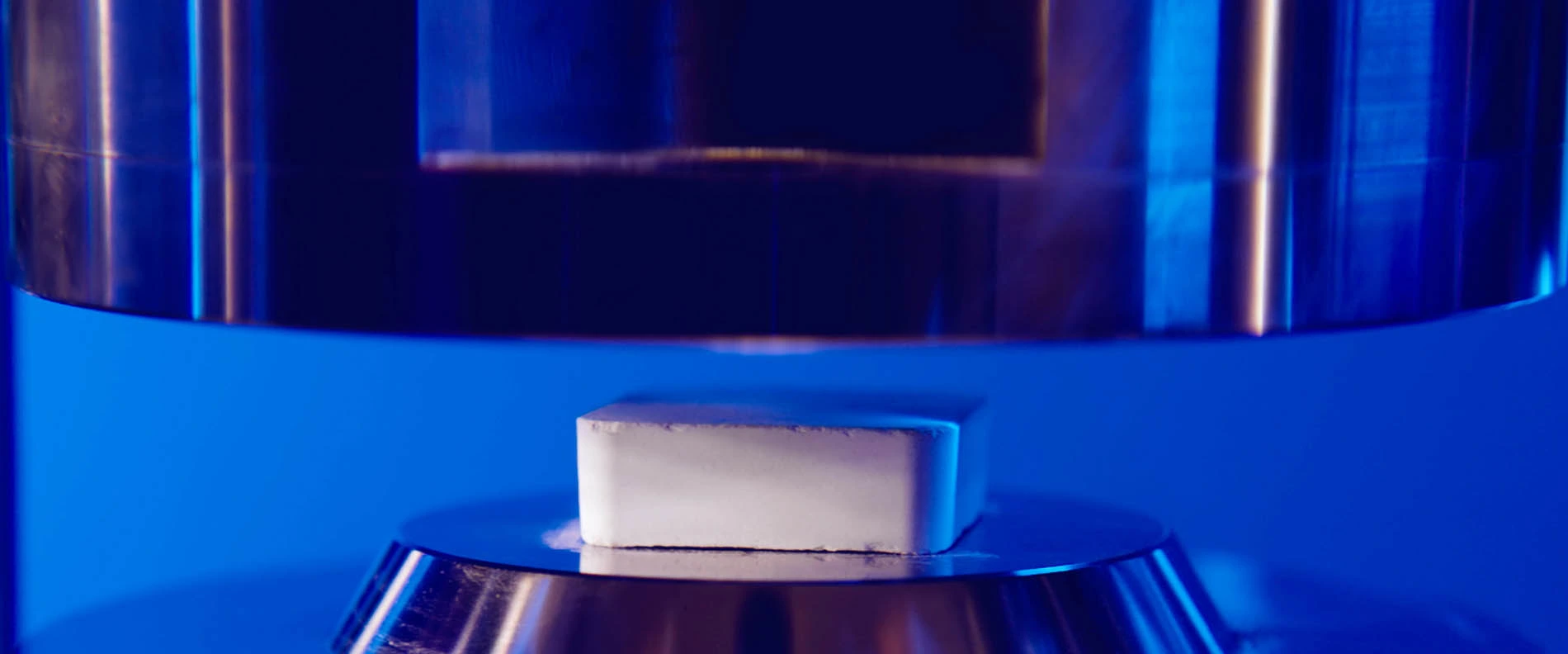

Aluminium oxide (Al₂O₃), also known as alumina, is a white crystalline powder used in various applications, including LED phosphors. As LED technology continues to evolve, one of its key components is LED phosphors. This article explores how aluminium oxide is utilised in LED phosphors, contributing to advancements in energy-efficient lighting.

1. Coating for Phosphor Particles

Phosphors play a crucial role in LED lighting by converting blue light emitted by LEDs into the desired colour spectrum. Aluminium oxide is used as a coating material for phosphor particles, enhancing stability, preventing interactions with the LED chip, and ensuring consistent light emission over time.

2. Improved Thermal Stability

LED phosphors often operate at elevated temperatures. Aluminium oxide’s exceptional thermal stability ensures that phosphors can withstand these conditions without degradation or colour shifting, contributing to the longevity and reliability of LED lighting systems.

3. Enhanced Light Dispersion

Aluminium oxide’s unique refractive properties improve the dispersion of light emitted by phosphors, ensuring even light distribution. This leads to enhanced colour uniformity and brightness across LED lighting panels or fixtures.

4. Protection Against Environmental Factors

LED lighting systems are often exposed to moisture, chemicals, and other environmental factors. Aluminium oxide coatings protect phosphor particles, ensuring consistent performance and safeguarding them from environmental degradation.

5. Control of Light Emission

Aluminium oxide not only offers protection but also helps control the direction and intensity of light emitted by LED phosphors. By strategically engineering the coating, manufacturers can tailor light emission characteristics to specific lighting needs.

Conclusion

Aluminium oxide (Al₂O₃) plays a pivotal role in LED phosphors, contributing to their stability, light dispersion, protection, and efficiency. As the demand for energy-efficient LED lighting grows, aluminium oxide’s properties enable phosphors to perform optimally in various applications, supporting the transformation of blue LED light into the vivid hues that illuminate our world.

You can learn more about our high purity alumina products, manufacturing and commercial availability by contacting our team at Alpha HPA.