Synthetic sapphire glass is a marvel of advanced materials, celebrated for its exceptional scratch resistance. This article delves into the world of synthetic sapphire glass, its primary component—aluminium oxide—and explores what makes it the ultimate scratch-resistant material.

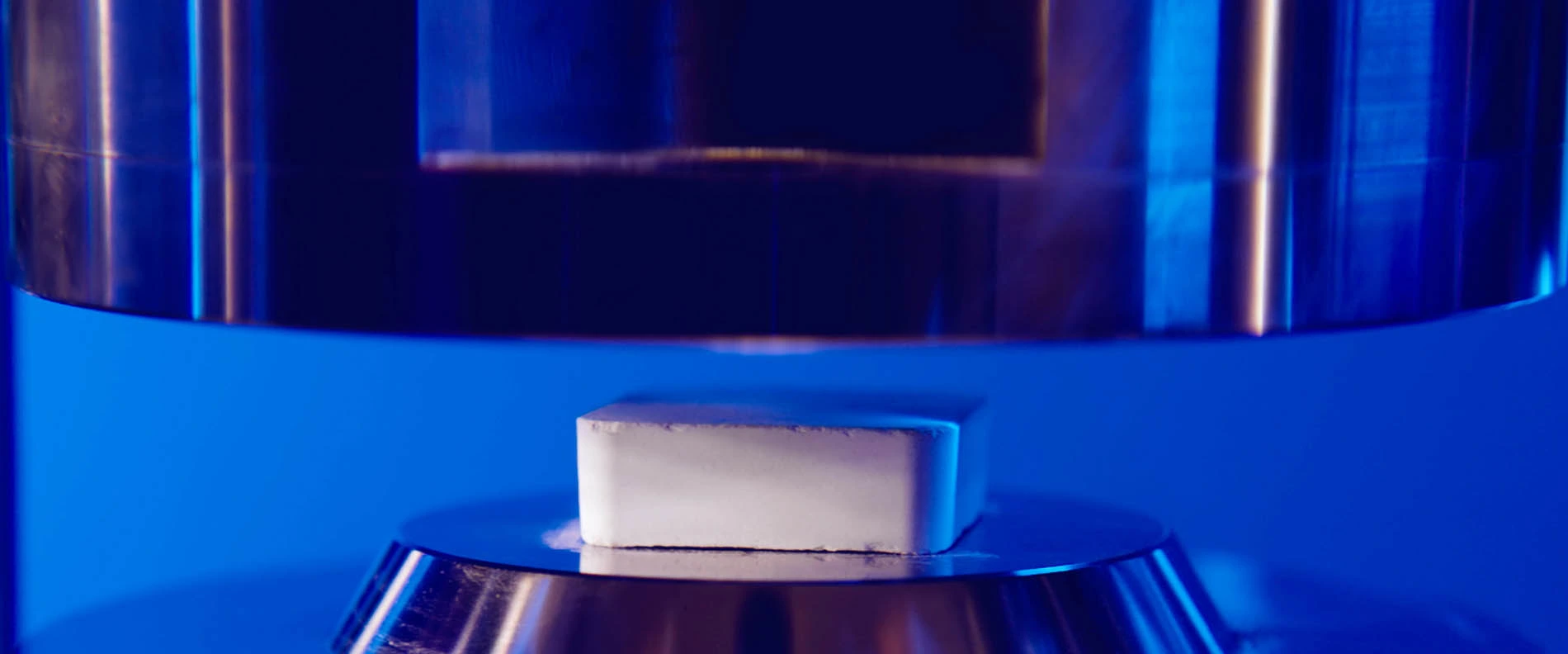

The Power of Aluminium Oxide

Synthetic sapphire glass is crafted from crystalline aluminium oxide (Al₂O₃), which mimics the properties of natural sapphire. Its transparency and hardness make it a prized material for protective covers in various applications.

The Science Behind Scratch Resistance

Synthetic sapphire’s crystalline structure is key to its scratch resistance. The robust lattice arrangement and strong bonds of aluminium oxide create remarkable hardness, which repels both indentation and surface scratches.

Navigating the Mohs Scale

Scoring a remarkable 9 on the Mohs scale, synthetic sapphire rivals the hardness of diamond (rated at 10). This places it ahead of everyday materials and metals like steel and aluminium, which are prone to scratches.

Durable and Versatile

Synthetic sapphire is not just used in luxury goods—it’s employed in camera lenses, watch faces, smartphone screens, and spacecraft windows. Its optical clarity, resilience, and resistance to extreme conditions make it a versatile material.

The Guardian of Visual Excellence

Synthetic sapphire glass embodies scientific ingenuity and practicality. Composed of aluminium oxide and engineered into a crystal-clear structure, it sets the standard for scratch resistance. This material ensures that screens remain pristine, providing devices with uncompromised visual experiences.

Inspiring Innovations

In the realm of materials science, synthetic sapphire glass continues to inspire innovation. Its legacy drives researchers to develop materials that are not only durable but also enhance interactions with the world around us.

You can learn more about our high purity alumina products, manufacturing and commercial availability by contacting our team at Alpha HPA.