Ceramics are materials that are made from inorganic, non-metallic compounds. They are typically hard, strong, and resistant to heat and corrosion. Ceramics are used in a wide variety of applications, including in the electronics, automotive, and medical industries.

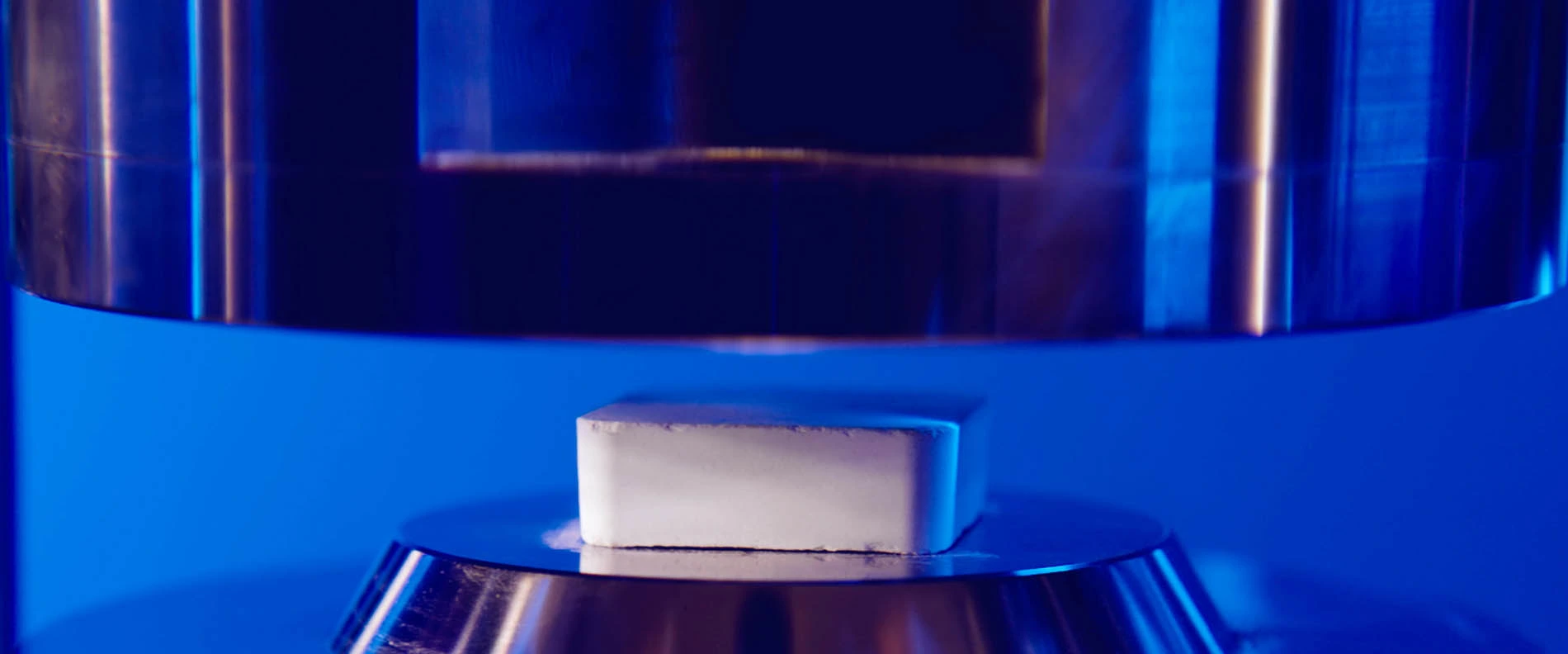

High purity alumina (HPA) is a type of alumina that has a purity of 99.99% or higher. It is made by purifying bauxite, which is the main ore of aluminium. HPA is a white, odourless, and tasteless powder. It is insoluble in water and most organic solvents.

HPA has a number of properties that make it a great fit for the ceramics industry. These properties include:

- High melting point: HPA has a melting point of 2,050 degrees Celsius (3,722 degrees Fahrenheit). This makes it a good choice for applications where the ceramic will be exposed to high temperatures.

- High hardness: HPA has a hardness of 9 on the Mohs scale. This makes it one of the hardest materials known.

- High chemical resistance: HPA is resistant to most acids and bases. This makes it a good choice for applications where the ceramic will be exposed to chemicals.

- High dielectric strength: HPA has a dielectric strength of 10,000 volts per centimetre. This makes it a good choice for applications where the ceramic will be used as an insulator.

- Low thermal expansion coefficient: HPA has a low thermal expansion coefficient. This means that it does not expand or contract much when exposed to heat. This makes it a good choice for applications where the ceramic will be exposed to temperature changes.

Due to its excellent properties, HPA is used in a variety of ceramic applications. These applications include:

- Substrates for semiconductor devices: HPA is used as a substrate for semiconductor devices, such as light-emitting diodes (LEDs) and transistors. The high purity and hardness of HPA make it a good choice for this application.

- Refractory materials: HPA is used in refractory materials, which are materials that can withstand high temperatures. HPA is used in applications such as kiln linings and furnace linings.

- Electrical insulators: HPA is used as an electrical insulator in applications such as circuit boards and capacitors. The high dielectric strength of HPA makes it a good choice for this application.

- Biomedical applications: HPA is used in biomedical applications, such as artificial joints and implants. The high biocompatibility of HPA makes it a good choice for these applications.

HPA is a versatile material with a wide range of applications. Its excellent properties make it a great fit for the ceramics industry.

Want to find out more about Alpha HPA products? Reach out to our Sales & Marketing Manager Derek Bogaert to set up a discovery call with Alpha HPA to discover more: hello@alphahpa.com.au