High Purity Alumina, or HPA, is an extremely versatile material that is widely used in the technology and automotive industries. In 2020, the HPA market was valued at USD 1.4 billion. As the world shifts to a more sustainable and energy-efficient future, the need for decarbonising technologies is paramount. With a commitment to global decarbonisation, Alpha HPA produces sustainable ultra-high purity aluminium products that are driving energy storage and other breakthrough technologies. In this article, we look at exactly what HPA is and its many applications.

What is High Purity Alumina?

High purity alumina (HPA) is a pure, high-grade form of non-metallurgical alumina or aluminium oxide (Al2O3). The application of HPA varies depending on its degree of purity. For instance, at Alpha HPA, we produce >99.995% (4N5) and >99.999% (5N) to be used in the manufacturing of products such as LED lights and lithium-ion batteries.

While there are many manufacturing processes of HPA, the most common is the hydrolysis of aluminium alkoxide. This process involves synthesising aluminium metal and alcohol to produce high purity aluminium alkoxide. HPA is then procured by calcination. Other existing processes include the production of HPA from aluminium metal feedstock or hydrochloric acid leach of kaolin clay. However, these processes are energy and labour intensive, produce high emissions, and create a significant amount of waste. At Alpha HPA, our production process using Smart SX Technology is extremely sustainable, low in energy consumption and low in waste.

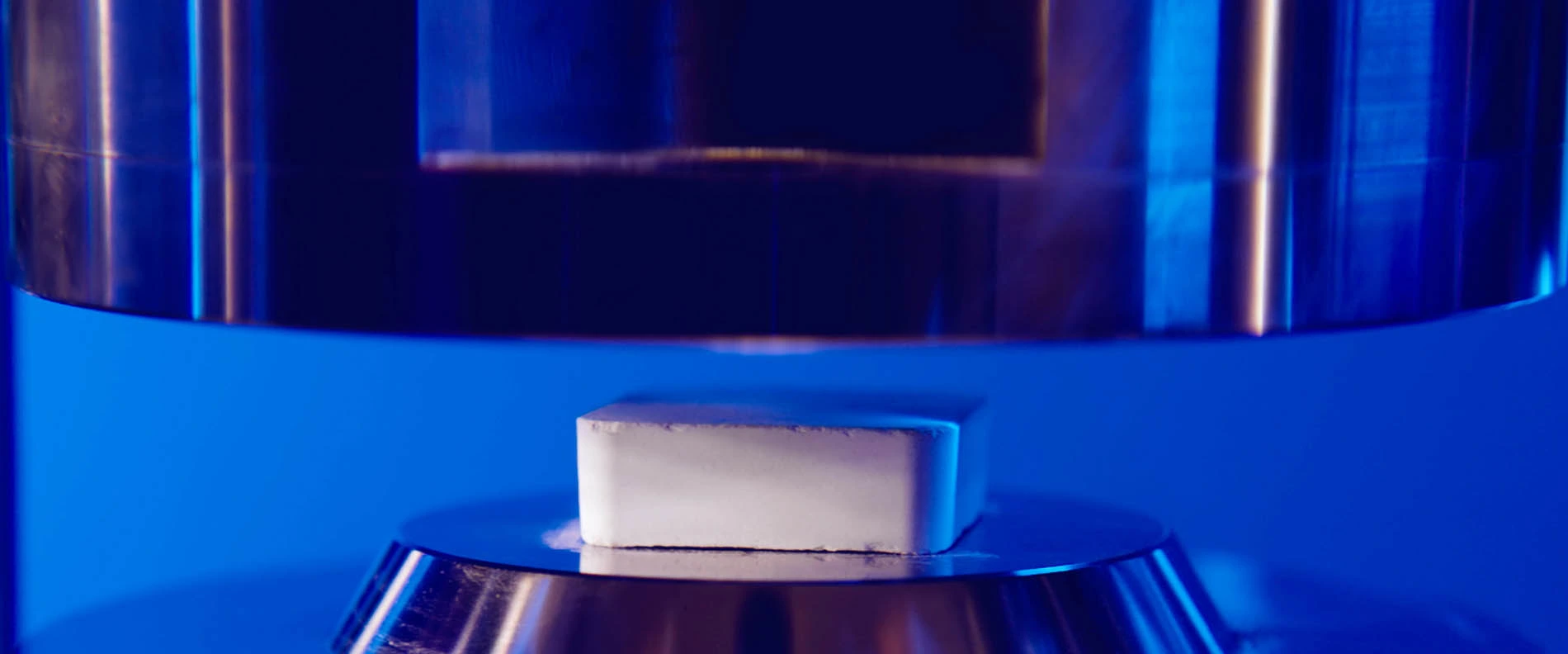

Depending on the end-use of the compound, HPA is generally produced in either a powder or pellet/tablet form.

Where Is HPA Being Used?

Over the last few years, we have seen an increased demand for sustainable, energy-efficient products and technology. With this demand also comes the growth of HPA, an essential compound for the manufacturing of LED (light-emitting diode) lights, lithium-ion batteries for electric vehicles and synthetic sapphire glass for wearable tech and smartphone camera lenses.

Global sales for electric vehicles amounted to 2.1 million in 2019, a 6% growth from the previous year. In 2020, global sales saw a 43% increase over 2019, with roughly 10 million electric vehicles on the road. The rise of electric vehicles does mean an increased need for lithium-ion batteries to power these cars. A key component of lithium-ion batteries is high purity alumina (HPA), where HPA is used to improve the batteries’ performance, reliability and safety.

With lighting accounting for nearly 10% of electricity usage in households, the need for energy-efficient lighting is growing exponentially. It is expected that this increase in energy-saving lighting will see a reduction in global electricity demand for lighting by 30-40% in 2030. Due to HPA’s thermal conductivity properties, this compound can produce LED sapphire substrates and aluminate phosphors, critical for converting blue light to white light.

We are also seeing an increase in the use of synthetic sapphire in various products, including LED substrates, lenses & glass, camera lights and watch faces. HPA is the primary ingredient for synthetic sapphire and cannot be substituted with alternative products.

What Are the Benefits of HPA?

There are many reasons why High Purity Alumina is such a valued industrial material, not only in Australia but globally. It possesses superior properties such as:

- Good chemical stability;

- A high melting point;

- Good thermal conductivity;

- The ability to withstand extreme temperatures;

- High mechanical strength;

- Scratch resistance; and

- High corrosion resistance.

So, how does HPA benefit its applications?

HPA and Lithium-ion batteries There are four key components of a lithium-ion battery; cathode, anode, electrolyte and separator. The primary function of the separator is to ensure cell safety and prevent contact between the anode and cathode while allowing lithium ions to pass through. A good battery separator should possess qualities such as chemical and thermal stability, strength and shutdown. As a key component of lithium-ion batteries, HPA-coated separators are used to improve the battery’s overall stability, safety and performance durability. They also provide exceptional heat dissipation and electrical insulation between the cathode and anode. Our 99.99% high purity alumina coating precursor material is used in coating both cathode and anode particles.

HPA and Synthetic Sapphire Natural sapphire is one of the toughest and most durable substances on earth. It is a form of aluminium oxide, which is why high purity alumina is the critical and primary ingredient for manufacturing synthetic sapphire. Synthetic sapphire holds the same properties and strength as natural sapphire gemstones, but without the colouring agents. Aside from its superior strength, other key properties of synthetic sapphire include scratch and corrosion resistance, chemical stability, the ability to transmit in UV, visible and infrared wavelengths, and the ability to withstand extreme temperatures. It is an ideal material for creating scratchproof glass for smartphones and premium watch faces.

Visit the Alpha Sapphire website to learn more.

Want to Learn More About High Purity Alumina?

If you would like to learn more about high purity alumina, our manufacturing process and its applications, please contact our team at Alpha HPA. You can also visit our investor centre to learn more about the developments of this material, our company reports, and investing in this sector.