Aluminium Oxide Coatings: Enhancing Safety and Performance

Lithium-ion batteries have become the backbone of modern technology, powering everything from smartphones to electric vehicles. However, their performance and safety have always been areas of concern. Enter aluminium oxide (Al₂O₃) and Boehmite (Al-O-OH) coatings – a game-changing innovation that is transforming the world of lithium-ion batteries. In this blog, we explore three remarkable ways Al₂O₃ coatings can improve the safety and performance of lithium-ion batteries, making them more reliable and robust than ever before.

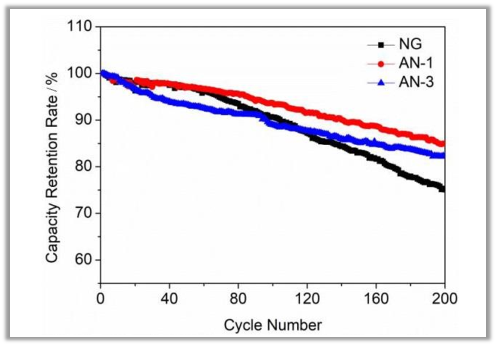

1. Improved Cycling Retention and Safety Performance (Tao et al., 2019):

The Al₂O₃ coating on anodes can lead to improved cycling retention and safety performance. This coating helps stabilise the solid electrolyte interface (SEI) and reduces undesired side reactions between the anode material and electrolyte. This results in better cycling stability and safety, as the SEI acts as a protective barrier that prevents electrolyte degradation and capacity fade over repeated charge and discharge cycles.

Reference: Tao, Z., Yi, J., & Lu, P. (2019). 3D porous Cu current collector with Al₂O₃ coating for high-performance Li-ion batteries. Journal of Alloys and Compounds, 790, 989-995.

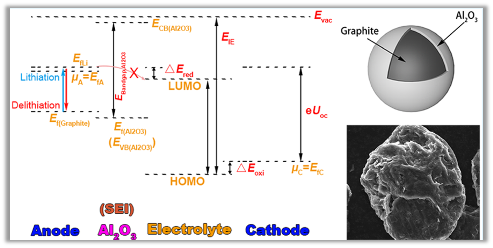

2. Act as an SEI Layer to Reduce First Cycle Loss and Improve Columbic Efficiency (Feng et al., 2016):

Applying an Al₂O₃ coating to the anode can serve as a passivation layer that forms a stable SEI during the first charging cycle. This SEI layer reduces the initial capacity loss and improves the columbic efficiency of the battery. By preventing excessive consumption of electrolyte and undesirable reactions during the first cycle, the Al₂O₃-coated anode enhances the overall efficiency and performance of the battery from its initial use.

Reference: Feng, K., Li, M., & Lu, L. (2016). Anodic Al₂O₃ Coating for Improved First-Cycle Coumbic Efficiency and Capacity Retention of Li-Ion Batteries. Journal of the Electrochemical Society, 163(10), A2276-A2280.

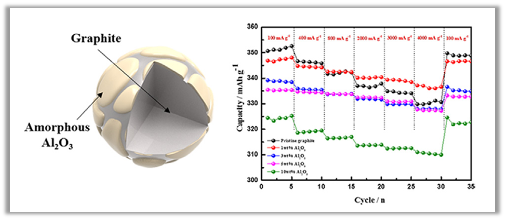

3. Improved Fast Charging Capacity (Kim et al., 2019):

Al₂O₃-coated anodes can enhance the fast-charging capacity of lithium-ion batteries. The coating improves the anode’s structural stability and mitigates the detrimental effects of fast charging, such as lithium plating and electrode degradation. This allows the battery to maintain higher capacity and better performance even under rapid charging conditions.

Reference: Kim, H., Kim, S., & Kim, J. (2019). Enhanced Li-ion mobility in Al₂O₃-coated graphite anode for high-power lithium-ion batteries. Electrochimica Acta, 296, 585-591.

Click here to find out more about our rapid, low-cost, ultra-high purity boehmite coatings for cathode and anode active materials to improve performance and safety for lithium-ion batteries.

Want to find out more? Our product development team bespoke engineer products for your individual requirements. Reach out to our Sales and Marketing Manager Derek Bogaert to set up a discovery call with Alpha HPA to find out more: hello@alphahpa.com.au