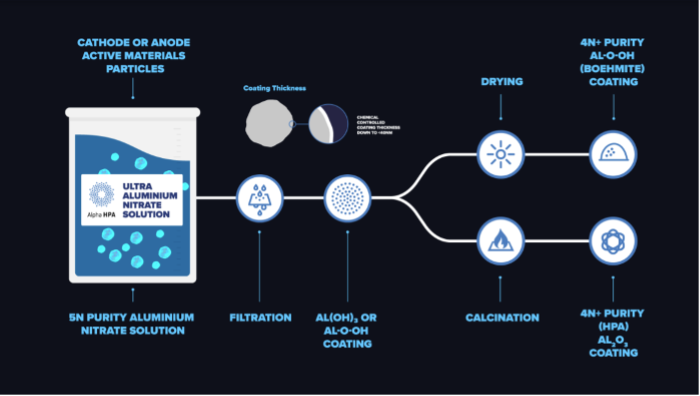

Rapid, low-cost, ultra-high purity boehmite coatings for cathode and anode active materials to improve performance and safety for lithium-ion batteries.

By solving the accessibility of large volume, high purity aluminium nitrate, Alpha HPA has unlocked the potential of fast and affordable ‘wet-process’ application of aluminium-oxide coatings onto both cathode and anode active materials. The process provides multiple battery performance benefits including improved safety and cycling retention, reduction in first cycle lithium loss and improved battery charging rates.

HPA in the lithium-ion battery cell

HPA is a key component in lithium-ion batteries, improving their performance, reliability and safety. Alpha HPA aluminium-oxide coatings have seen:

- 20% increase in power retention

- 4% increase in first cycle capacity

- No first cycle lithium loss, with the al-oxide coat operating as the sei layer

- Increased safety with al-oxide coat replacing the sei

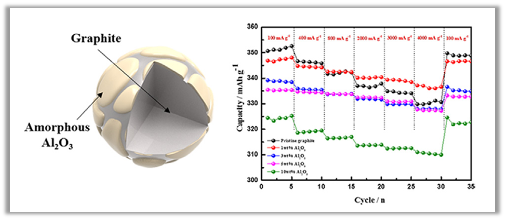

Anode (negatively charged electrode contact):

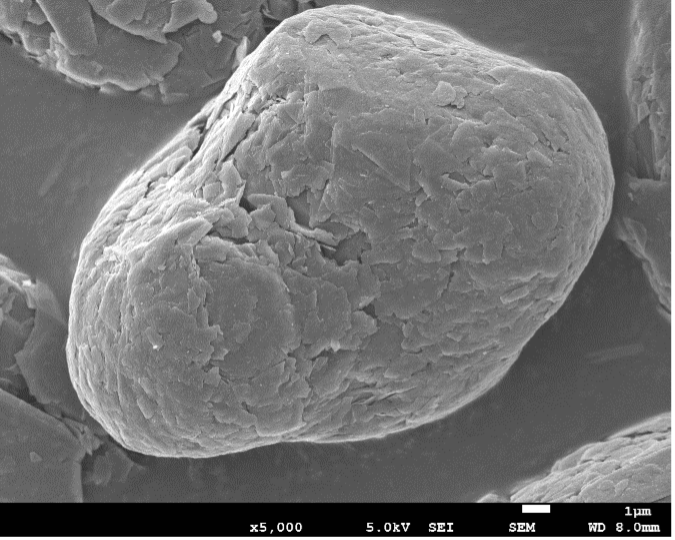

Uncoated graphite anode active material (before)

Coated graphite anode active material (after)

Alpha HPA’s Al-oxide coatings offer several advantages for anode active materials including:

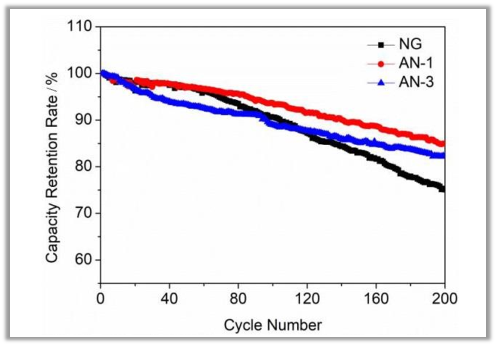

1: Improved cycling retention and safety performance (source: Tao et al., 2019)

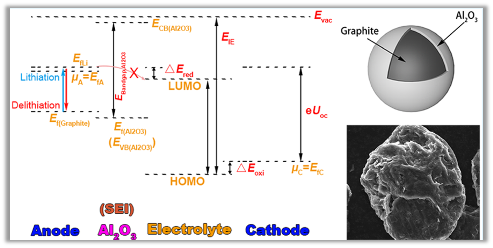

2: To act as an SEI layer and reduce first cycle loss and improve Columbic efficiency (source: Feng et al., 2016)

3: Improved fast charging capacity (source: Kim et al., 2019)

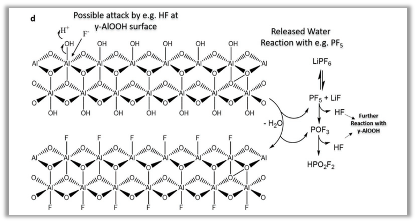

Cathode (positively charged electrode contact):

Uncoated graphite cathode active material (before)

Coated graphite cathode active material (after)

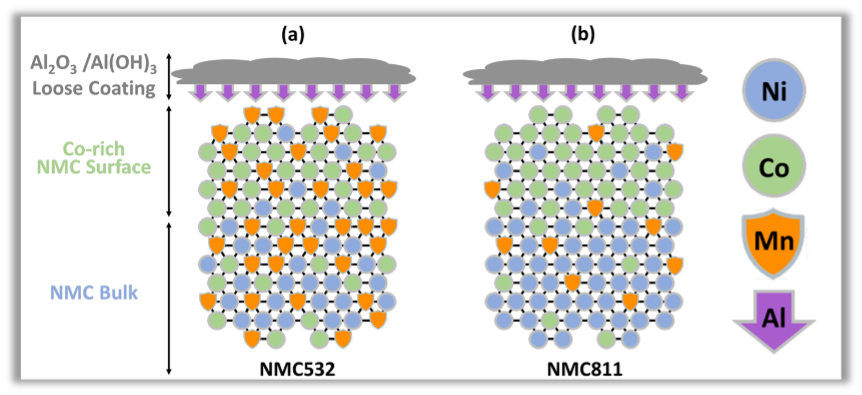

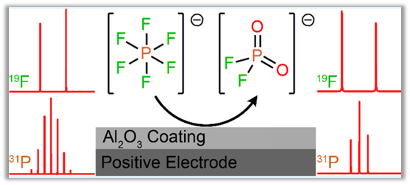

Alpha HPA’s Al-oxide coatings offer several advantages for cathode active materials including:

1 : HF passivation (by Al-O-OH) (source: Klein et al., 2022)

2: Improved cathode stability of high-Ni cathode (source: Han et al.)

3: HF passivation with improved cycle life (Al2O3) (source: Dahn et al., 2019)

Separator:

HPA coated separator provides exceptional heat dissipation and electrical insulation between the anode and cathode, allowing the lithium-ions to move between charging and discharging cycles.

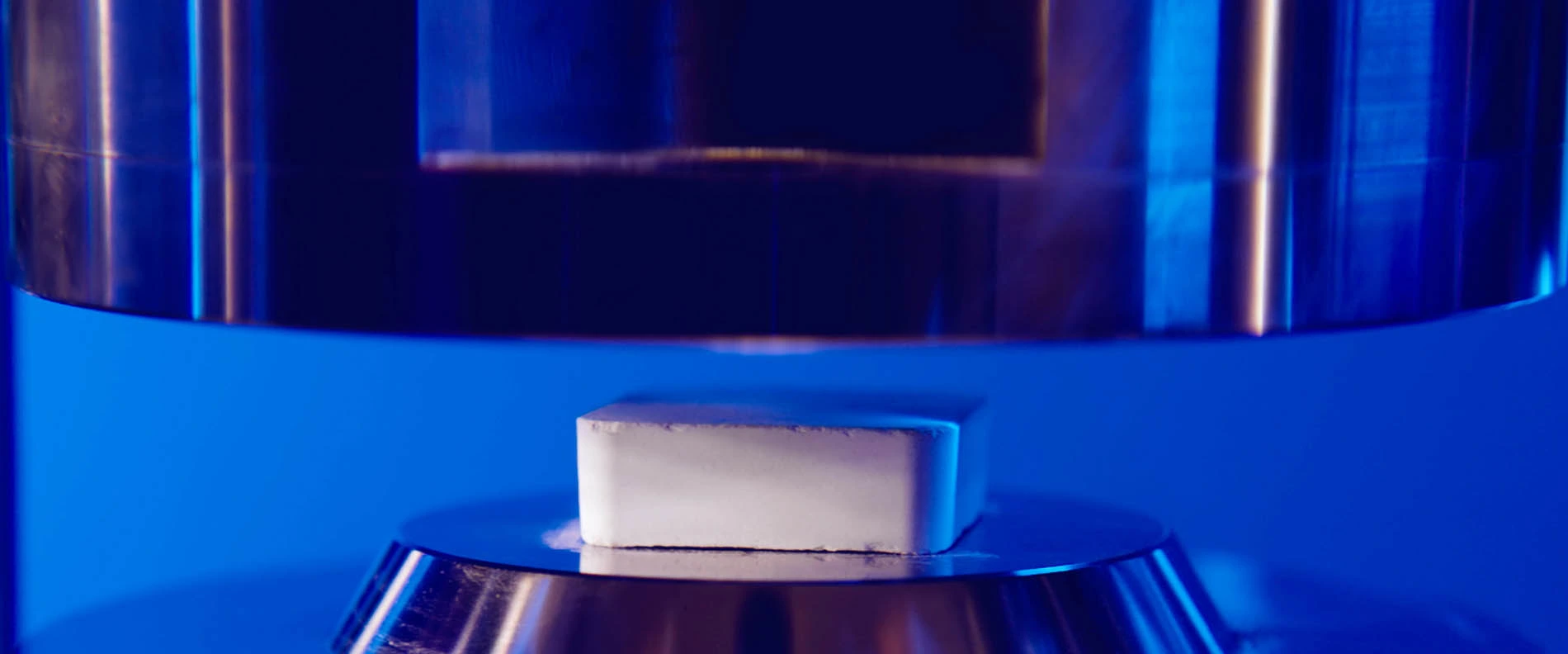

Lithium-ion battery separator coated with Alpha’s Ultra Alpha Phase Alumina Powder)

Alpha HPA’s Ultra-Coat ProcessTM has revolutionised the coating of cathode and anode active materials for lithium-ion batteries. The process provides multiple benefits including improved performance, reliability, and safety and is a significant step towards creating high-performance lithium-ion batteries that are affordable and accessible to a wider range of consumers.

Want to find out more? Our product development team bespoke engineer products for your individual requirements. Reach out to our Sales and Marketing Manager Derek Bogaert to set up a discovery call with Alpha HPA to find out more: hello@alphahpa.com.au